🔧 Product Overview

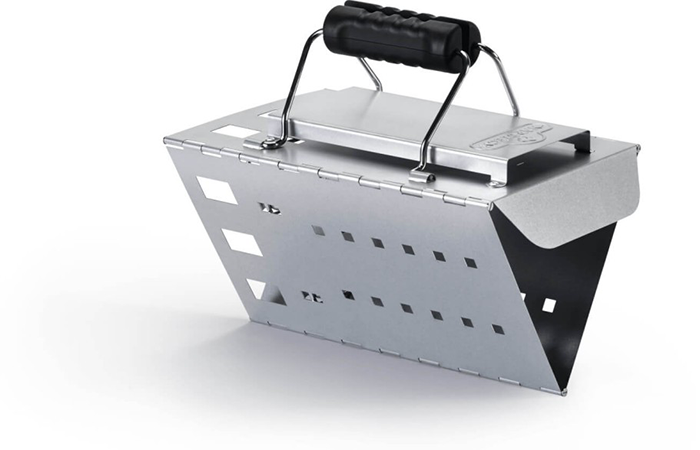

Every successful grilling experience starts with ignition. Our finished parts for chimney-style fire starters are designed to support reliable, fast, and safe charcoal lighting through controlled airflow and thermal integrity.

These components are produced using high-precision laser cutting, CNC bending, and durable powder coating to meet the demanding use cases of outdoor environments. Handles, ventilation holes, and fire cone sections are all assembled from components tailored for structural stability and efficient heat flow.

Whether you manufacture complete chimney starters or require subassemblies, we offer repeatable quality and scalable output.

⚙️ Key Features

-

Heat-Tolerant Design

Made from galvanized steel, stainless steel, or coated carbon steel to resist warping and oxidation under high temperatures. -

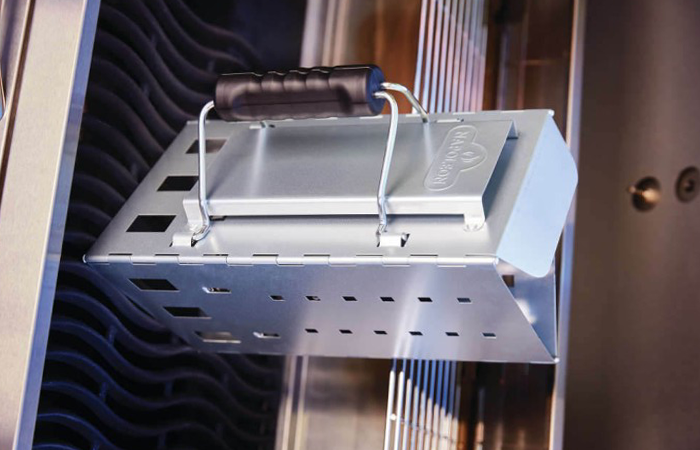

Optimized Airflow Geometry

Vent holes and cutouts are precisely positioned to accelerate ignition and reduce charcoal waste. -

Ergonomic Integration

Handle and shield bracket designs ensure safe, cool-touch usage during operation. -

Structural Reliability

Folded seams, reinforced tabs, and bracket locking positions enhance strength and assembly precision. -

Flexible Customization

Sizes, hole layouts, branding cutouts, and accessories adjustable per your design.

📐 Technical Specifications

| Parameter | Details |

|---|---|

| Materials | Galvanized Steel / SUS304 / Q235 with Coating |

| Panel Thickness | 0.6mm – 1.5mm |

| Surface Finish | High-temp Powder Coating / Zinc Plating / Brushed |

| Max Assembly Size | Ø180mm × H280mm (customizable) |

| Heat Resistance | Up to 600°C surface exposure |

| Features | Vent cutouts, folded edges, rivet-ready tabs |

🧩 Application Scenarios

These finished parts are essential in:

-

Chimney-style fire starter cone walls

-

Base trays with ignition slots

-

Handle mount brackets

-

Safety heat shields

-

Retail-ready starter kits (OEM/ODM)

Each component is crafted not just to fit—but to ignite confidence with every use.

🛠 Why Choose Baoxuan

-

🧷 In-House Control – Laser cutting, bending, coating, and rivet assembly all done under one roof

-

🔥 Heat Endurance Verified – All parts undergo 500°C surface and deformation testing

-

🎯 Fit and Finish Guaranteed – 3D matching to your final assembly layout

-

🌍 OEM Branding Ready – Supports laser-cut logos, stamping, and packaging customization

-

📦 Flexible Batches – From 300 sets to 30,000+, scalable and stable

FAQ – Chimney Starter Finished Parts

❓1. What is the best material for chimney-style fire starter parts?

We recommend galvanized steel for cost-efficiency or SUS304 stainless steel for high-heat resistance and outdoor durability.

❓2. Can you supply pre-assembled kits?

Yes. We offer options for partial sub-assembly or flat-packed kits, depending on your packaging needs.

❓3. What surface finish holds best against soot and heat?

Matte powder coating in dark tones resists thermal discoloration and soot adhesion, maintaining clean aesthetics after repeated use.

❓4. Do you support prototype samples?

Yes. Prototypes can be delivered within 5–7 working days upon drawing confirmation.

❓5. Can you help with product optimization?

Absolutely. We provide feedback on airflow positioning, handle ergonomics, and structural load points to improve performance and safety.

Reviews

There are no reviews yet.