🔧 Product Overview

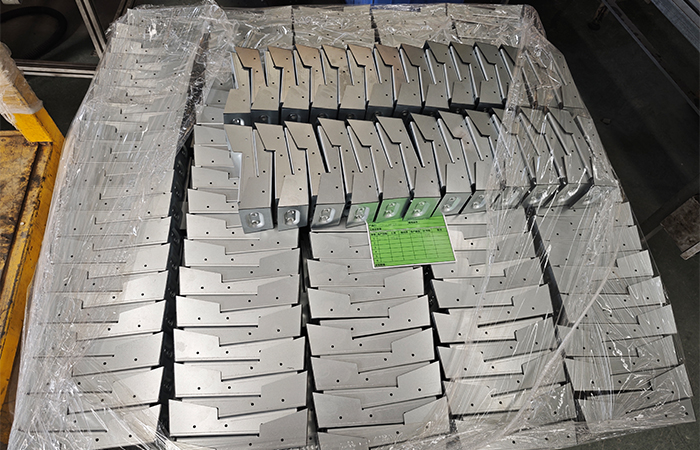

A strong foundation defines how long your barbecue lasts. Our barbecue grill base components are built to support the entire weight of gas or charcoal cooking systems. Every bracket, plate, and structural frame is cut, formed, and coated to stand up to the rigors of outdoor use—sun, rain, and constant handling.

We don’t just make metal parts. We craft solutions that connect safely, align precisely, and hold firmly under heat and pressure.

⚙️ Key Features

-

Reinforced Structure Design

All components are laser-cut and formed with bracing and folded edges to enhance mechanical strength. -

Outdoor-Ready Surface Protection

Powder-coated or galvanized finishes resist corrosion and peeling even after prolonged exposure. -

Exact Hole Layouts and Interfaces

Supports hinges, wheels, gas tanks, and ignition modules—customized to match your model. -

Easy Assembly Integration

Chamfered holes, key slots, and guide tabs simplify alignment during final assembly. -

Reliable Load Capacity

Depending on material, base frames support up to 120 kg static load.

📐 Technical Specifications

| Specification | Detail |

|---|---|

| Materials | Q235, SUS304, AL5052 |

| Thickness Range | 1.2mm – 3.0mm |

| Max Part Dimensions | 1200mm × 700mm |

| Surface Finishes | Powder coating (outdoor grade), hot-dip galvanizing, brushed stainless |

| Tolerance Control | ±0.1mm (hole-to-edge and bending) |

| Features | Integrated mount slots, pre-drilled casters, reinforced ribs |

🧩 Application Scenarios

Our grill base parts are commonly used in:

-

Standalone gas barbecue carts

-

Foldable base frames for portable grills

-

Enclosed BBQ cabinets with drawers or gas bottle storage

-

Mobile wheeled base systems

-

Outdoor kitchen series bases

Every part is prepared with one goal—to provide the stable support your grill needs to perform safely and reliably.

🛠 Why Choose Baoxuan

-

🧷 Integrated Manufacturing – Cutting, forming, powder coating and assembly under one roof

-

🔍 Design Matching Accuracy – Built exactly to your drawings with 3D verification if needed

-

🧪 Coating & Weld Strength Testing – Internal QC includes salt spray test and load-bearing trial

-

📦 Assembly-Ready Delivery – Parts packed with clear labeling and protection pads

-

🌍 OEM & Export-Qualified – RoHS / REACH compliance and international packaging options

FAQ

❓1. Can these base parts be integrated with caster wheels or gas bottle mounts?

Yes. We can design holes or brackets to mount wheels, propane tanks, or even leveling feet. If you have specifications, we’ll make sure it aligns.

❓2. How do you ensure structural strength for heavy grills?

We use finite element analysis (FEA) during design phase and apply folded flanges, ribs, or thicker gauge sheets to strengthen load-bearing surfaces.

❓3. What coating performs best outdoors?

We recommend outdoor-grade powder coating or hot-dip galvanizing for long-term rust protection. Black matte, graphite, or silver finishes are popular for BBQ units.

❓4. Can I request a prototype before full production?

Yes. We offer sample orders with rapid turnaround, typically delivered in 5–7 working days depending on finish and volume.

❓5. Do you support knock-down assembly kits?

Absolutely. If you’re designing a DIY or modular unit, we can deliver parts with guide pins, labeled packaging, and assembly manuals on request.

Reviews

There are no reviews yet.