These enclosures are engineered with durability, dust resistance, waterproofing, and EMI shielding in mind. Constructed primarily from CNC-machined high-performance aluminum alloys, they combine structural integrity with lightweight performance to meet stringent requirements for flight endurance and payload efficiency.

Why Our Solutions Work

High-Strength Protection for Motors

Drone motors are vulnerable to impact and environmental exposure during operation. Our enclosures are built for mechanical strength and precise fit, offering optimal protection tailored to your specifications.

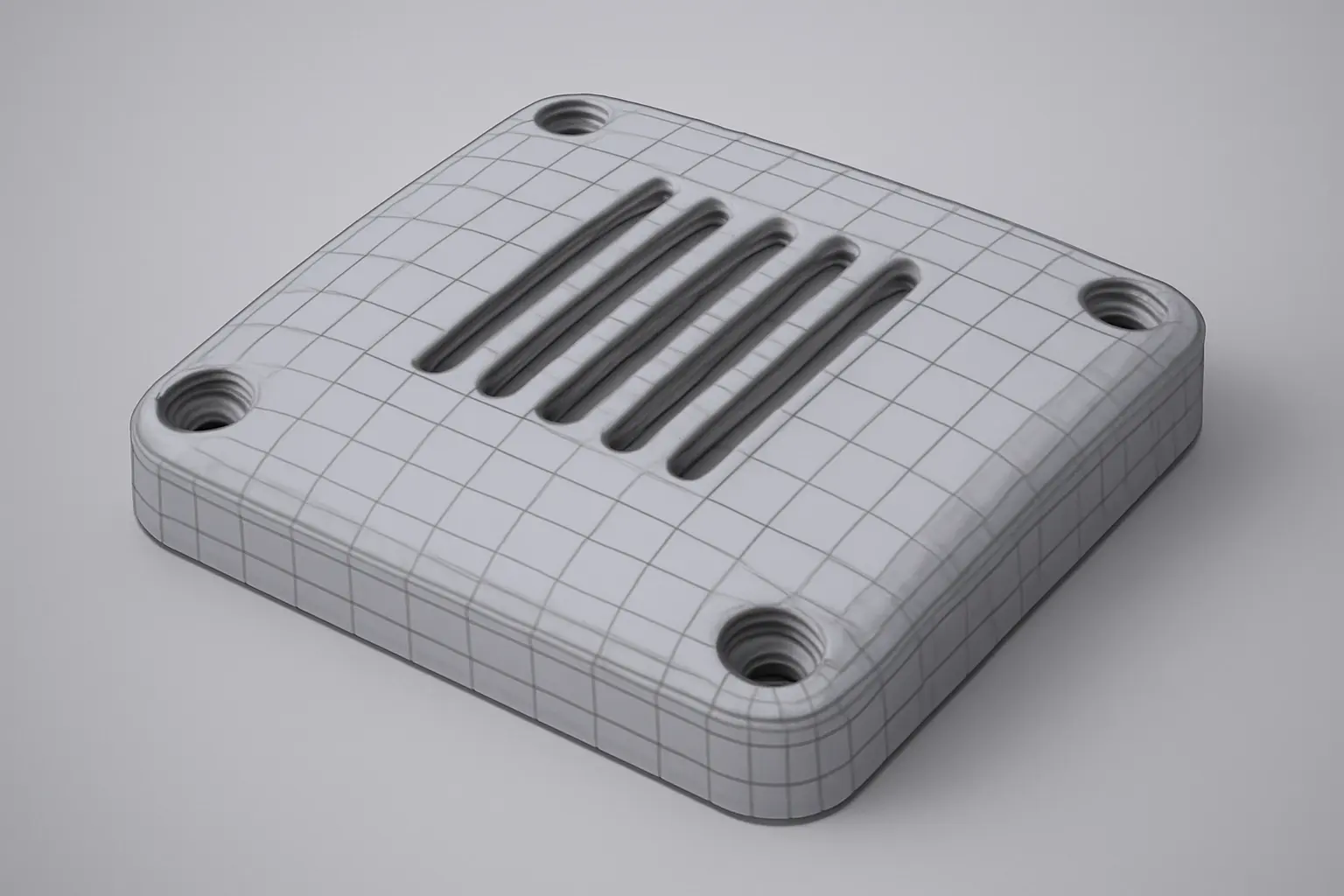

Thermal Management for Electronics

Flight controllers, ESCs, and video transmission modules generate significant heat. We incorporate heat dissipation designs, including ventilation slots, surface treatments, and conductive interfaces to maintain system stability.

EMI Shielding in Complex Environments

In environments with high electromagnetic interference, performance fluctuations can occur. We offer fully enclosed electronic module EMI shielding enclosures with conductive anodizing or nickel plating and grounding layouts to improve interference resistance.

Lightweight Design

We use high strength-to-weight ratio materials such as 7075 aluminum, combined with structural optimization like hollowing and ribbing, while maintaining tight tolerances to ensure rigidity and reduce weight.

Fast Assembly and Maintenance

Our designs support modular layouts with quick-release fasteners, standard screws, and pre-defined service ports, enabling easy assembly and efficient maintenance.

Based on these needs, we have developed a range of high-performance components, including CNC aluminum motor cover, custom drone metal shield, and other specialized enclosures.

Capabilities & Technical Highlights

| Category | Specification |

|---|---|

| Materials | 6061-T6 aluminum, 5052 aluminum sheet, 304 stainless steel, magnesium alloy |

| Precision | Laser cutting ±0.1mm, CNC bending ±0.3°, assembly tolerance ±0.2mm |

| Structures | One-piece motor guards, modular electronics housings, quick-assembly brackets |

| Surface Treatment | Anodizing, plating, powder coating, brushing, sandblasting, anti-corrosion coating |

| Heat Management | Ventilation holes, airflow channels, thermal transfer interfaces, EMI mesh covers |

| Mounting Options | Screw mounts, sliding rails, clip-on quick locks |

We specialize in producing lightweight drone motor guard and modular drone electronics housing, which are compatible with multirotor, VTOL, and fixed-wing UAV platforms.

Application Scenarios

-

Energy Inspection Drones: High-strength motor enclosures with EMI-shielded compartments

-

Security Surveillance Drones: Metal housings for video modules with integrated cooling features

-

Agricultural Drones: Dust- and waterproof ESC enclosures with motor heat protection

-

Mapping/Surveying Drones: Integrated metal casings for flight control and imaging systems

-

Emergency Communication Drones: Fully shielded electronics compartments with anti-interference structure

Frequently Asked Questions (FAQ)

Can you manufacture metal covers based on our motor and module specifications?

Yes. We offer fully customized solutions. By providing your component dimensions, mounting holes, and interface details, we can produce precise drone motor housing and UAV electronic module casing designs to match.

Do your enclosures support EMI shielding?

Yes. Our electronic module EMI shielding enclosures use conductive coatings, metallic mesh, and grounding structures to enhance anti-interference capability—especially for video transmission and control systems.

Can heat dissipation features be integrated into the enclosures?

Absolutely. Our custom drone metal shield solutions include heat sinks, air channels, and ventilated designs that improve long-term thermal stability of electronics.

Are the motor covers corrosion-resistant and suitable for outdoor use?

We recommend anodized aluminum or powder-coated stainless steel for optimal corrosion resistance, suitable for use in agricultural, coastal, or dusty operating environments.

Do you offer modular fast-mounting solutions?

Yes. We provide modular drone electronics housing options with sliding rails, clips, and quick-release screws, allowing easy maintenance and fast replacement.

What is your lead time and minimum order quantity?

MOQ starts at just 5 units. Prototype production typically takes 5–7 working days. Bulk order delivery depends on complexity, with expedited service available.

Contact Us

Guangzhou Baoxuan Precision Manufacturing Co., Ltd.

Website: www.baoxuanmetal.com

Email: [email protected]

Phone: +86 13600457738 (WeChat available)

For drone OEM solutions, click here

Reviews

There are no reviews yet.