Product Overview

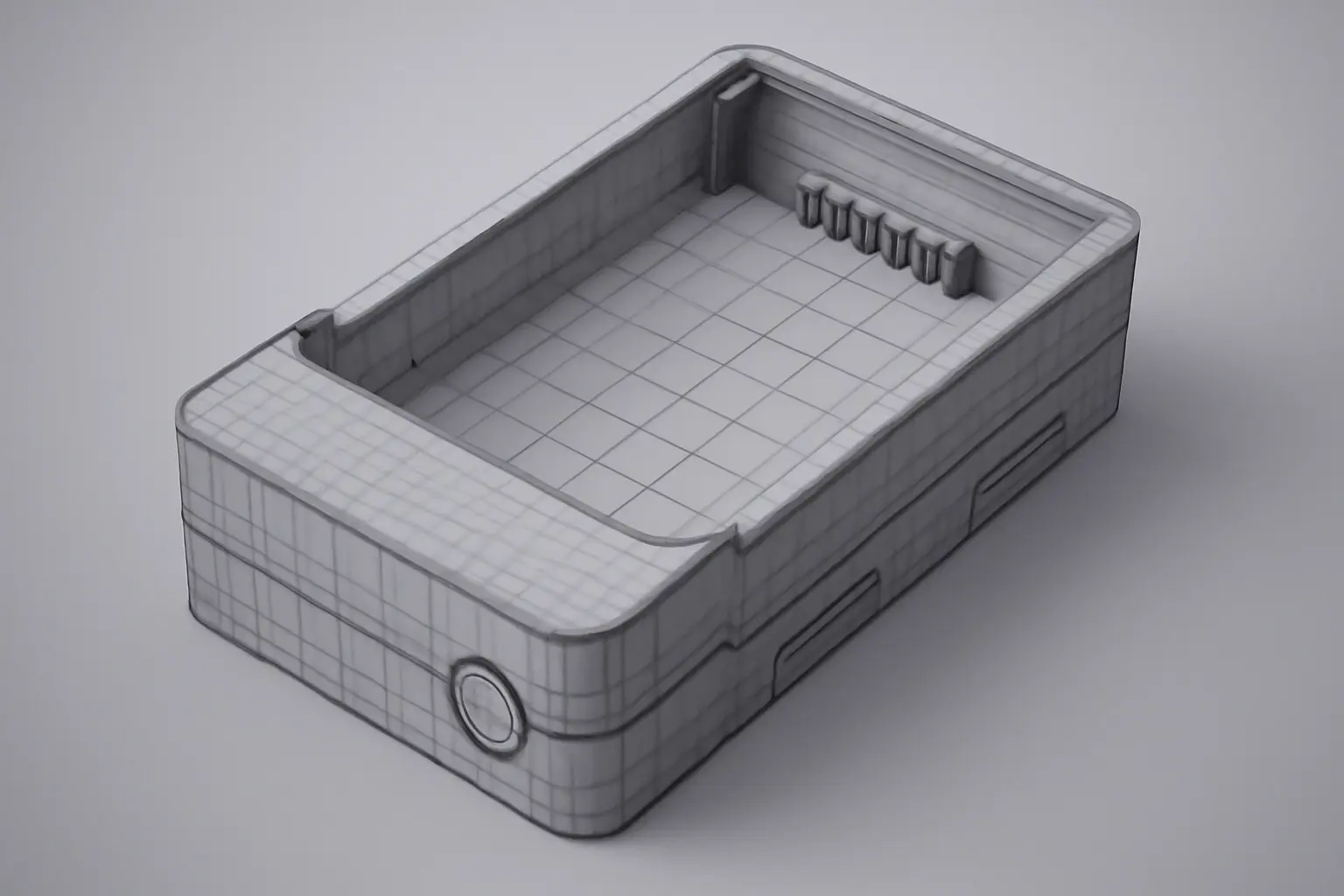

Trays and brackets are designed and manufactured based on battery model, wiring layout, insertion frequency, and thermal management requirements, supporting multirotor, fixed-wing, and VTOL drones.

Application Fields

- Agricultural drones

- Power line inspection drones

- Emergency response drones

- Aerial photography and mapping drones

- Industrial and military-grade drones

Advantages of Baoxuan’s Battery Trays / Brackets

1. Solid Structure & High Assembly Precision

The battery compartment is a key zone of any drone. We provide machining precision up to ±0.1 mm, ensuring tight fit and battery stability.

2. Easy Battery Swapping

Quick-release buckles, guide rails, and slots are available based on battery shell design for faster installation and reduced errors.

3. Lightweight for Extended Endurance

Made from 6061-T6 aluminum or magnesium alloy with optimized structural design, offering strength without excess weight.

4. Corrosion Resistance

Available surface finishes include anodizing (black/silver/olive green), powder coating, anti-fingerprint, and anti-corrosion coatings for challenging environments like farming and high humidity.

5. Heat Dissipation

We can design custom ventilation holes or channels for high-power batteries to enhance safety and extend battery life.

Processing Capabilities & Technical Support

- Materials: Aluminum alloy, magnesium alloy, stainless steel, titanium alloy

- Size: Customized per drawing; max part size up to 1000 × 800 mm

- MOQ: 5 units; supports prototyping, rapid iterations, and mass production

- Processes: German laser cutting + CNC bending + TIG welding/rivet press fitting

Case Studies

- Agricultural drone tray: Anodized black aluminum with reinforced ribs; high shock resistance; delivered in bulk to drone manufacturers

- Industrial inspection drone bracket: Magnesium alloy reduced weight by 18%; enhanced thermal performance with hot-swappable design

Why Choose Baoxuan

- 20 years of experience in metal processing; deep understanding of drone assembly needs

- Full in-house capabilities: from cutting to final inspection

- Engineering support for structural optimization

- Flexible small-batch production for faster prototyping

Technical Drawing Requirements

To ensure quality and assembly accuracy, please prepare the following documents when requesting a quote or prototype:

1. 3D Model File (Recommended)

- Formats: STEP (.stp/.step), IGES (.igs/.iges), Parasolid (.x_t/.x_b), SolidWorks (.sldprt)

- Content: Full structure, mounting location, battery orientation, screw specs

2. 2D Engineering Drawing (Required)

- Formats: PDF, DWG, DXF

- Content:

- Full dimensions, tolerances, hole locations

- Material type, surface finish (e.g. anodizing color, plating type)

- For welding/bending parts: bending direction, angle, tolerance

3. Assembly Instructions (Optional)

- Insertion direction, connector type, screw/insert locations

- Support sample pieces, videos, or hand sketches for clarity

We also offer modeling or design assistance upon request with basic sketches and functional requirements.

FAQ: Frequently Asked Questions

Q1: Can you customize trays/brackets based on my battery dimensions?

Yes. Just provide the battery dimensions, fixing method (screw/clamp/magnetic), and usage environment (vibration, temperature, humidity), and we will propose the best-fit solution.

Q2: Do your brackets support hot-swapping?

Yes. We design slots, alignment holes, and support structures tailored for hot-swapping, ideal for inspection drones.

Q3: What is your machining precision?

Laser cutting precision is ±0.1 mm, bending accuracy within ±0.3°, ensuring tight fit and no battery movement.

Q4: Can you help optimize the design?

Yes. If you only have basic dimensions or old designs, we can help reduce weight, improve mounting, or enhance shock resistance.

Q5: What is the minimum order quantity? Do you support prototyping?

MOQ is 5 units. We support prototyping and small-batch production for testing or validation.

Q6: What surface finishes are available? Are they corrosion-resistant?

We offer anodizing (various colors), powder coating, brushing, and plating. These finishes provide corrosion, scratch, and fingerprint resistance.

Q7: What file formats do you accept?

- 3D models: STEP, IGES, Parasolid, SolidWorks

- 2D drawings: PDF, DWG, DXF If unavailable, physical samples or sketches are accepted for reverse modeling.

Q8: What’s the lead time? Can you expedite?

Typical prototype lead time is 5–7 working days. Mass production depends on process and volume (usually 2–4 weeks). Expedited production is available upon request.

Q9: Which drone platforms are supported?

We support multirotor, fixed-wing, and VTOL drones in agricultural, inspection, emergency, industrial, and security sectors.

Q10: Do you offer international shipping and English communication?

Yes. We ship globally and provide bilingual communication and documentation. Remote video reviews and onsite inspection are available.

Contact Us

Guangzhou Baoxuan Precision Manufacturing Co., Ltd.

Location: C2-A Building, Hepingwei Industrial Zone, Yongning Street, Zengcheng District, Guangzhou, China

Phone: +86 13600457738

Email: [email protected]

Website: www.baoxuanmetal.com

For drone OEM solutions, click here

Reviews

There are no reviews yet.