We once got called in to troubleshoot a surveillance UAV that kept returning with misaligned footage and strange payload jitter. After pulling it apart, the problem was embarrassingly simple — the internal bracket plates holding the thermal camera weren’t machined to spec. One screw boss was off by half a millimeter, and the baseplate had been laser-cut from soft, uncoated sheet stock. Combine that with a few hard landings, and everything shifted mid-flight. Sensors can’t work right if the housing doesn’t hold.

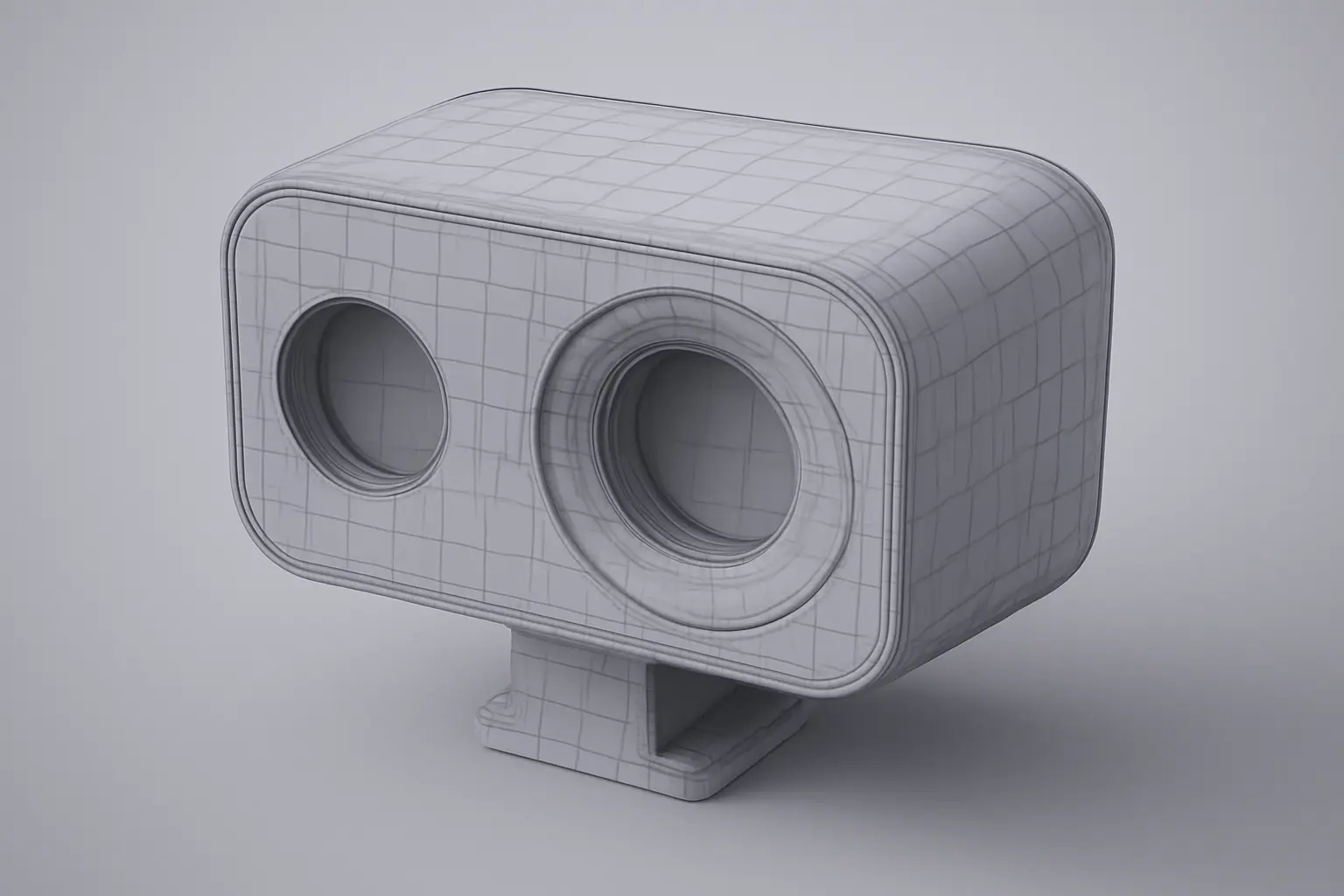

That’s why we started building machined parts for metal components of drone sensor and camera bracket housings that are designed to handle real-world stresses — not just bench testing. These aren’t generic stamped pieces. They’re precision-machined, properly finished, and tailored for structural performance under vibration, wind loads, and uneven landings.

Built Around the Sensor — Not the Other Way Around

When you’re trying to align a LiDAR module, a thermal camera, and an IMU in a tight UAV shell, even a 0.2mm tolerance stack-up starts to matter. That’s where CNC work comes in. Our CNC machined drone bracket parts are cut, tapped, bent, and assembled with one goal in mind: holding your critical electronics in the exact position they’re supposed to be — and keeping them there, even after hours in the air.

The housing plates, sensor brackets, and reinforcement tabs we machine integrate cleanly into custom-built assemblies. Whether you’re prototyping a custom metal camera housing or doing a 200-unit production run, these components form the backbone of a dependable UAV payload stack.

Core Technical Specs

-

Main Purpose

-

Hold camera/sensor components rigidly in place

-

Absorb and distribute flight shock and minor impact

-

Maintain fixed orientation — no creeping, sliding, or rattle

-

-

Material Selection

-

5052-H32 / 6061-T6 aluminum: great strength-to-weight, corrosion-resistant

-

SUS304 stainless steel: stronger, heavier — often used in high-EMI or rugged-duty drones

-

Sheet thickness: 1.0mm to 2.5mm depending on load-bearing points

-

-

Processing Capabilities

-

Laser cutting for accurate outer profiles and slots

-

CNC bending for precision-formed L-, U-, or enclosed housings

-

TIG/spot welding for joined parts — tight seams, minimal distortion

-

Tapping for M2.5 / M3 holes, or press-rivet studs for modular builds

-

Surface finishes: anodizing, powder coat, or matte black spray to reduce glare

-

Optional: laser marking for part IDs or assembly alignment

-

We also offer drone mounting plate prototyping — great for testing new sensor configurations before locking down a final assembly.

Smarter Installation. Fewer Field Surprises.

Installers don’t have time to fiddle with misaligned holes or strip soft threads. These machined parts come prepped for field assembly — countersunk holes where needed, pre-set wiring slots, and consistent hole spacing that actually matches what the drawing says.

Mounting layouts support standard 20x20mm and 30x30mm hole patterns, but we also handle full custom specs. Add precision aluminum sensor mount clips or internal EMI shields as needed. We can even bond copper foil for RF-critical modules.

We’ve seen too many field repairs where a few cents’ worth of machining could’ve saved a hundred-dollar camera.

Real-World Advantages

-

Parts hold up after hours of airborne vibration — not just a bench test

-

Anti-oxidation coatings resist corrosion in coastal or high-humidity ops

-

Smooth bends and proper material temper prevent stress cracking

-

Custom fitments eliminate the need for washers, tape, or zip-tie hacks

This is the kind of custom metal fabrication for drones that actually earns its keep once you start flying the thing.

FAQ — What Clients Usually Ask

Q1: Can I get these parts for early-stage builds?

Yes — we offer rapid machining of UAV brackets for fast-turn prototyping. Just send your files or even a sketch.

Q2: Do you support special hole patterns for non-standard cameras?

Definitely. It’s part of our drone payload bracket OEM service — we customize hole placement, shape, and cable routing points.

Q3: Will these parts work in cold or hot environments?

The materials are rated from -20°C to +80°C, with proper surface finishing to prevent rust or oxidation over time.

Q4: Can you integrate EMI shielding into the bracket parts?

Yes. We can apply conductive paint or bond internal copper layers to reduce interference.

Q5: What about labeling or part ID on each bracket?

Laser marking is supported — part number, logo, or alignment marks can all be etched directly during the final stage.

Let’s Build Something That Actually Fits

If you’re tired of re-drilling holes in the field or chasing weird sensor shifts, these machined components might just be your fix. We know what it takes to keep drone payloads stable — and we’re set up to help from the first prototype all the way to small-batch production.

Shoot us your CAD file or just tell us what you’re working on — we’ll help you get the right metal parts dialed in, minus the guesswork.

Contact Us

Guangzhou Baoxuan Precision Manufacturing Co., Ltd.

Website: www.baoxuanmetal.com

Email: [email protected]

Phone: +86 13600457738 (WeChat available)

For drone OEM solutions, click here

Reviews

There are no reviews yet.