We once got a call from a drone integrator whose thermal issues weren’t just causing shutdowns — they were warping internal boards. The root cause? A flat aluminum cover with no ventilation and laughable heat dissipation. They had ESCs cooking under a sealed lid, no airflow paths, and zero heat sink structure. Even worse, the so-called “vent slots” were just decorative. That drone didn’t just run hot — it failed three minutes into hover testing.

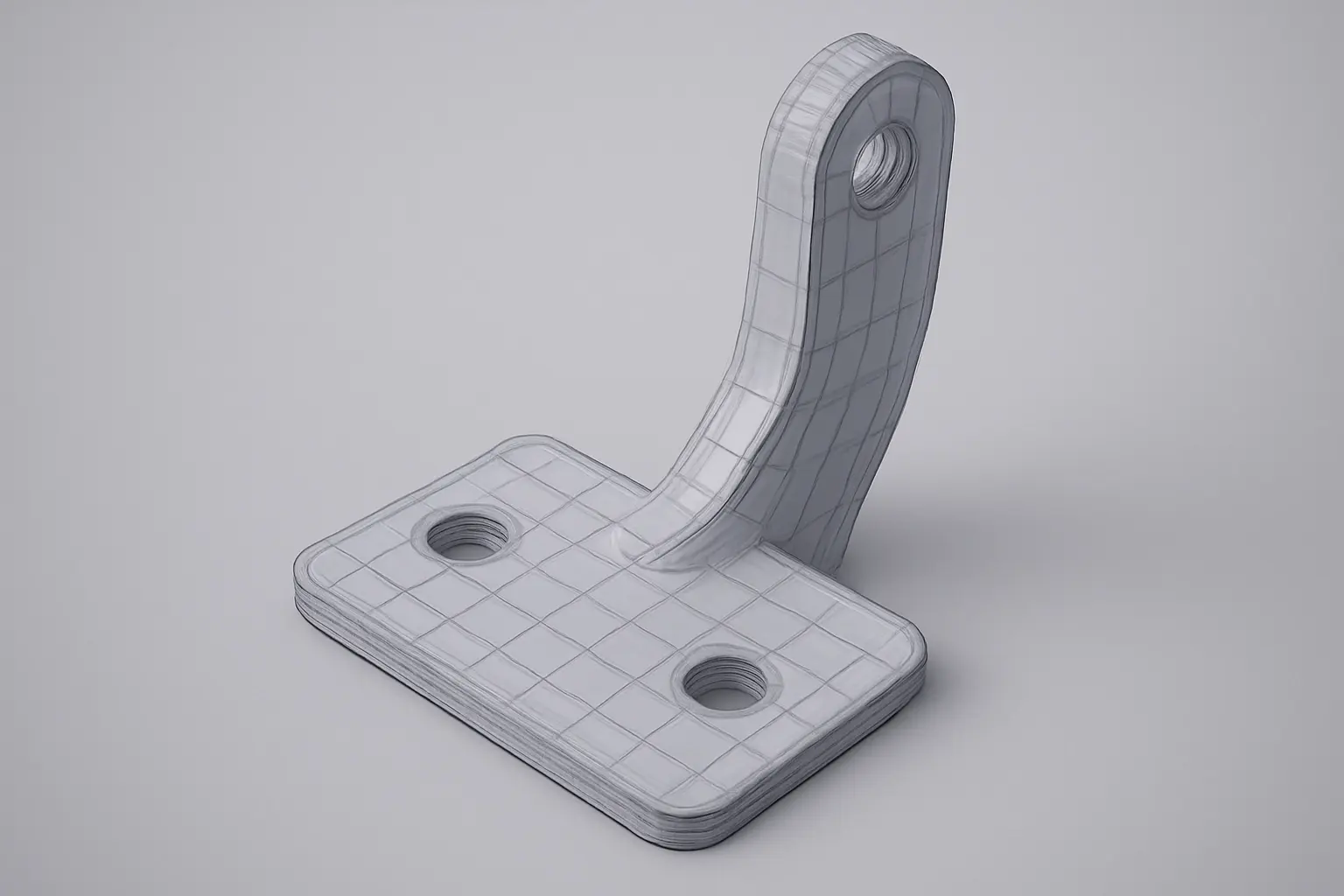

This drone aluminum heat sink with fins was designed to fix that kind of mess — practically and reliably.

Designed for Real-World UAV Thermal Management

This isn’t just a cosmetic top panel. It’s a UAV ventilation mesh plate built for active roles in both cooling and protection. We use 5052-H32 or 6061-T6 aluminum for strength, formability, and decent thermal conductivity. Fins are either stamped or bent directly from the sheet (if you’re okay with 3–5 mm height), or modular for more aggressive dissipation.

The ventilation mesh is no afterthought — we use stainless or aluminum mesh spot-welded or pressed in, sitting flush behind laser-cut vents. That gives you at least 40% open area for airflow while keeping out larger debris.

In short: your ESCs and boards get to breathe. And stay alive.

Tech Specs That Actually Matter

-

Material: 5052-H32 / 6061-T6 aluminum

-

Panel Thickness: 1.5 mm–2.5 mm (balancing rigidity and weight)

-

Fins: 2–5 mm height, formed or attached

-

Mesh Opening Ratio: ≥40% (customizable)

-

Surface Finishes: Anodized or powder-coated

-

Flatness Tolerance: ±0.3 mm over 200 mm span

-

Fasteners: M3 / M4 holes with optional PEM nuts

-

Mesh Fitment: Spot-welded or jig-pressed for alignment

Built the Way Field Techs Want It

We use laser cutting or CNC punching for exact contours, slot geometry, and thermal vents. Fins are formed in the same setup if space allows, or we rivet/weld them on for higher-profile designs.

Edges get rounded and vent holes are deburred — not just for safety, but because we’ve seen wires get sliced when someone skipped that step.

Need this to double as an EMI shield? No problem — we can include gasket tracks and even coat it if you’re dealing with noisy RF environments. One client used this on a fixed-wing mapping UAV with sensitive GNSS hardware and saw a measurable drop in onboard noise.

Real-World Benefits

In one ruggedized inspection drone, we swapped in this drone heat sink fin panel after their top shell started distorting near the power rail. Post-upgrade, onboard temps dropped by 12–15°C under load, with no noticeable drag impact.

Another customer, running a multi-rotor in tropical humidity, liked that the mesh didn’t trap moisture like foam grills. Just air in, junk out.

This is the kind of drone thermal control that works quietly — until you remove it and realize what it was saving you from.

FAQ — Real Questions We’ve Heard

Can I mount this on a carbon fiber airframe?

Absolutely — just let us know your mounting points. We can pre-press PEM nuts or slot the holes to fit tolerance gaps.

Does this panel need active cooling to work?

Nope. It’s passive — it relies on prop wash or airflow from forward motion. But if you’re running 100% throttle in hover, give it room to breathe.

Can the mesh clog up with dust?

It’s possible, but we design the pattern to shed particles. Hex or oval slots help reduce buildup compared to round holes.

What surface finish holds up best outdoors?

Anodizing’s great for general exposure. If you’re near saltwater or fertilizer dust, powder coating offers better corrosion resistance.

Can I get my logo or serial numbers engraved?

Yep. Laser marking or engraving is easy to add — just send us a vector file or even a screenshot.

Let’s Get Your Setup Running Cooler

Need a custom perforated mesh panel, taller fins, or a specific air vent layout? Send over your CAD, or just a rough sketch. We’ll help turn the thermal side of your drone into one less thing you have to troubleshoot.

Contact Us

Guangzhou Baoxuan Precision Manufacturing Co., Ltd.

Website: www.baoxuanmetal.com

Email: [email protected]

Phone: +86 13600457738 (WeChat available)

For drone OEM solutions, click here

Reviews

There are no reviews yet.