A few months back, a customer in the smart agriculture space came to us frustrated. Their logistics drone had crashed during an automated delivery test — not because of a flight error, but because the landing gear folded on impact. The aluminum they used was thin, the bends weren’t reinforced, and the whole assembly was riveted too close to the edge. One hard touchdown on uneven soil, and snap — main bracket sheared.

That’s a scenario we’ve seen more than once. Which is why we started building metal processed and bent parts for drone landing gear that are designed with real-world abuse in mind. Not theoretical payloads or lab landings. We’re talking uneven terrain, gusty winds, and the occasional operator mistake.

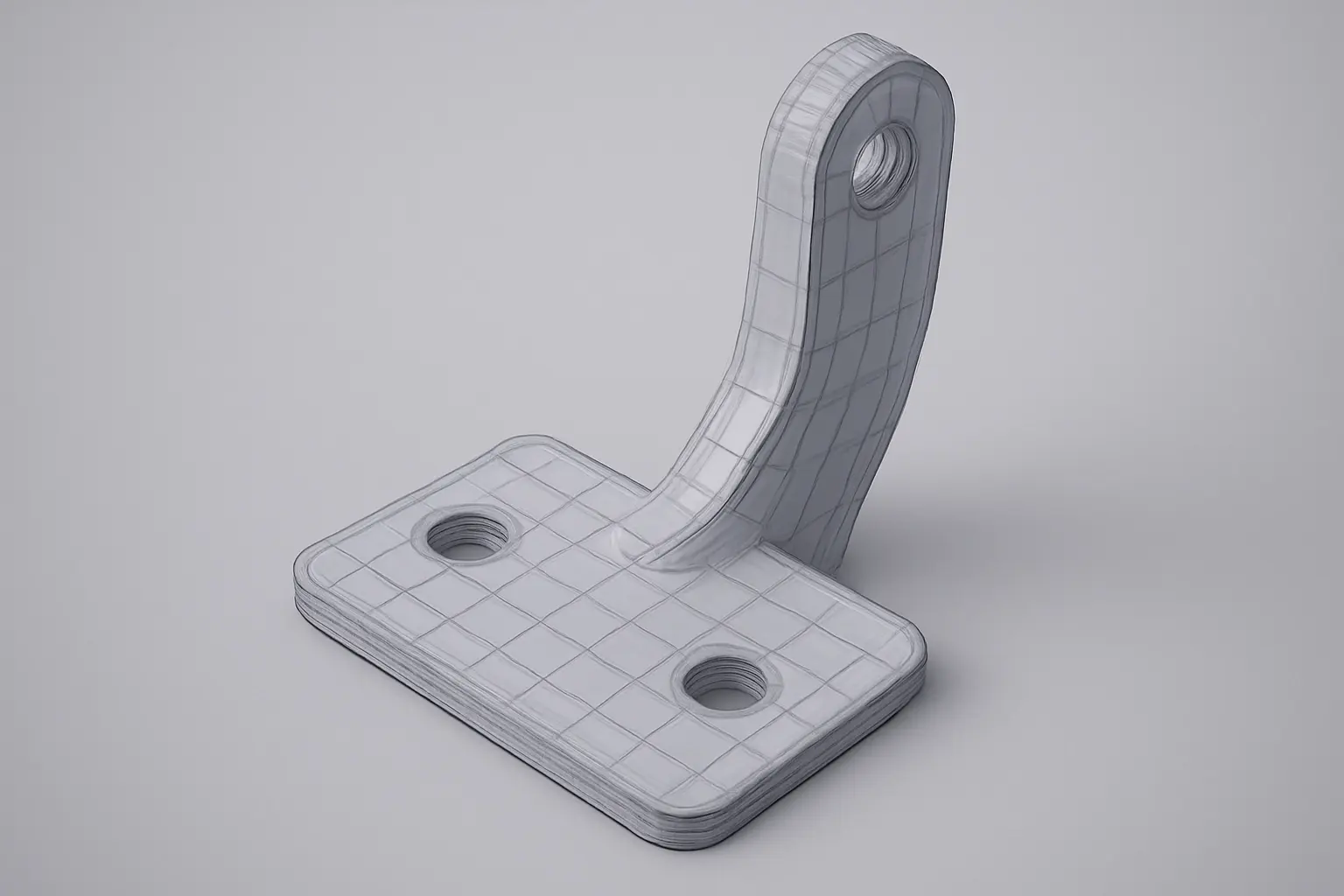

Tough Where It Counts — Not Just a Pretty Frame

These aren’t ornamental parts. They’re designed to absorb vertical impact, resist side loads, and still be swappable in the field. Whether it’s a drone metal structure for logistics delivery or a low-altitude surveillance rig, landing gear needs to perform when it matters most — not just hold up for a photoshoot.

We build with the kinds of tolerances and bend radii that matter in high-use systems. Each part is laser-cut, CNC bent, and field-validated with repeated landing cycle tests.

They’re commonly used on:

-

Agricultural UAVs

-

Mapping/multirotor platforms

-

Medium-lift drones used in parcel drop or powerline inspection

Technical Overview

1. Purpose & Application

-

Structural support during takeoff/landing

-

Absorbs and distributes impact force

-

Ensures frame doesn’t twist or transmit stress to avionics

2. Materials & Thickness

-

5052-H32 / 6061-T6 aluminum: corrosion-resistant and light

-

SUS304 stainless steel: more robust for rugged or marine environments

-

Standard thickness: 2.0–3.0 mm

-

Light builds (1.5 mm) possible for smaller drones, but we recommend caution with unsupported bends

3. Processing Methods

-

Laser cutting for edge quality and hole tolerance

-

CNC bending with controlled radii to avoid cracking

-

Spot/TIG welding for ribs or multi-piece assemblies

-

Edge rounding — especially near cable pass-throughs

-

Surface finishes: anodizing (common), powder coat (black or gray)

-

Optional PEM inserts, usually M3 or M4 for structural joints

4. Design & Installation Notes

-

Hole patterns matched to base frame specs

-

Optional shock-absorbing interfaces (pads, rubber washers)

-

For long arm extensions, we often recommend adding relief slots — improves fatigue life

-

Works well in custom UAV parts for environmental monitoring or drone platforms operating in high-humidity regions

5. Performance in the Field

-

Survives repeated impact — many clients report 100+ landing cycles with no deformation

-

Field-replaceable without special jigs or disassembly

-

Surface-treated to resist oxidation, moisture, and abrasion

-

We’ve had clients operating in coastal zones with zero visible corrosion after six months — that’s solid performance

6. Customization Options

-

Custom geometries: folding arms, skid legs, V-braces

-

Custom color options: matte black, natural aluminum, tactical grey

-

Small-batch support for drone bracket housing for smart agriculture trials or pilot production

-

CAD support and file feedback for fast iteration

Why It Works Better Than Off-the-Shelf Gear

-

You get clean bends, not stress fractures waiting to happen

-

Mounting lines match your real assembly — not just a drawing

-

Shock loads get spread through the frame, not dumped on the flight controller

-

Field techs appreciate not having to file down bad holes or realign warped parts

It’s one of those drone components that seems minor — until a landing breaks it.

FAQ — Real-World Questions from Field Teams

Q1: Can these parts be used on folding landing gear arms?

Yes, we’ve made V-leg and folding-style landing parts for multirotors. Just flag the hinge area in your design.

Q2: Are these compatible with high-clearance mapping drones?

Absolutely. We can adjust leg height and add mounting tabs — especially useful for drones with belly-mounted sensors or high-precision drone imaging systems.

Q3: Do you offer anodized finishes in specific colors?

Yep. Black and grey are common, but we can do natural or custom anodizing if needed for visibility or branding.

Q4: Will these hold up on rough terrain or auto-landings?

They’re built for that. We’ve tested them under real-world vibration and impact conditions — we even had a client using them on a firefighting drone sensor bracket assembly rig.

Q5: What’s the fastest turnaround for prototyping a new shape?

If your CAD file is ready, we can often ship within 5–7 working days — including surface finish.

Let’s Build Landing Gear That Doesn’t Fold

If your current landing setup feels like it’s just “good enough” — or worse, if it’s already failed — this is probably the upgrade you’re looking for. We speak in bend angles and frame stress, not just catalog numbers. Send over your drawing or sketch, and we’ll help you lock in a design that’ll hold up when your drone touches down — every time.

Contact Us

Guangzhou Baoxuan Precision Manufacturing Co., Ltd.

Website: www.baoxuanmetal.com

Email: [email protected]

Phone: +86 13600457738 (WeChat available)

For drone OEM solutions, click here

Reviews

There are no reviews yet.