Product Overview

Every mechanical system depends on the quality of its individual parts.

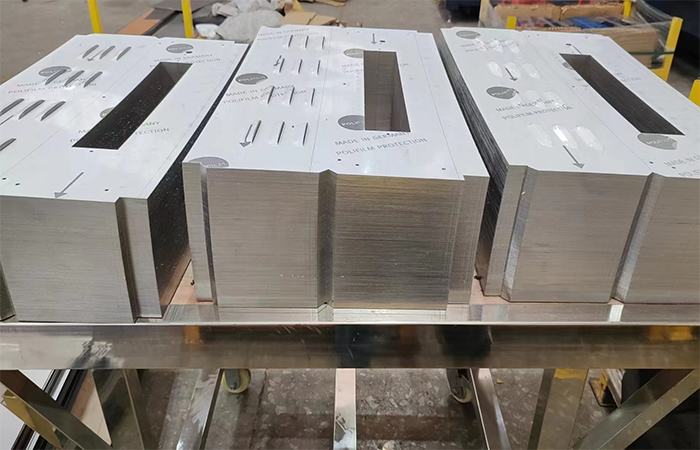

Our Numerical Control (NC) Discrete Parts Processing service focuses on the accurate machining of non-repetitive, uniquely shaped components that demand consistency, precision, and strength.

These are not off-the-shelf parts—they are engineered responses to your machine’s exact structure. At Baoxuan, we handle the full cycle: from digital file to finished product, combining CNC punching, laser cutting, bending, and surface treatment to deliver dependable results.

Key Features

-

Versatile NC Programming – Handles irregular contours, variable hole patterns, and complex slots with ease

-

Tight Tolerance Assurance – Controlled within ±0.1mm across part dimensions

-

Multi-Station Support – Discrete parts may involve punching, folding, welding, and finishing in one workflow

-

CAD-to-Part Precision – Directly linked to your 2D or 3D technical files

-

Real-World Reliability – All parts undergo measurement checks before packaging

Technical Specifications

| Parameter | Details |

|---|---|

| Materials Supported | Carbon Steel, Stainless Steel (304, 316L), Aluminum (5052, 6061), Copper |

| Thickness Range | 0.8mm – 8.0mm |

| Max Processing Size | 2000mm x 4000mm |

| Hole and Cutout Precision | ±0.1mm |

| Surface Options | Powder Coating, Zinc Plating, Brushed, Anodized, Electrolytic Polishing |

| File Formats Accepted | DWG, DXF, STEP, IGES, PDF |

| Batch Support | 1 to 10,000+ units |

Application Scenarios

Our NC discrete parts serve a variety of industries where customization is the rule—not the exception:

-

Electrical control cabinets

-

Rail and transport interior panels

-

Enclosures for power and telecom modules

-

Smart recycling equipment brackets

-

Precision subassemblies for automation frames

Every piece is manufactured with purpose—and built to integrate.

Why Choose Baoxuan

-

Process Accuracy – Automated NC control plus manual QA checks

-

Multi-Step Integration – Cutting, punching, bending, welding, and coating

-

Engineer-to-Engineer Communication – Our team speaks your design language

-

Sample to Mass Production – Flexible capacity for any stage of your development

-

RoHS/REACH Compliance – Global shipment with full compliance documentation

Frequently Asked Questions (FAQ)

1. What types of parts qualify as “discrete components”?

These are individually designed parts, often low-volume, and not mass-manufactured molds. They may differ in size, hole position, profile, or surface finish.

2. Can you produce from CAD drawings?

Yes. We accept 2D drawings (.DXF/.DWG) and 3D files (.STEP/.IGES). If needed, our engineering team can help adjust geometries for fabrication.

3. What’s your tolerance control range?

We maintain ±0.1mm for cutouts, bends, and assembly holes. This ensures perfect fit for high-precision industrial parts.

4. Do you support combined operations (cutting + bending + powder coating)?

Absolutely. Many discrete parts require multiple processing steps, and we support them all in-house to ensure seamless transitions and consistent quality.

5. What is your minimum order quantity (MOQ)?

We support small batch orders starting at 5–10 units, depending on part complexity. Mass orders are also welcome.