🔧 Product Overview

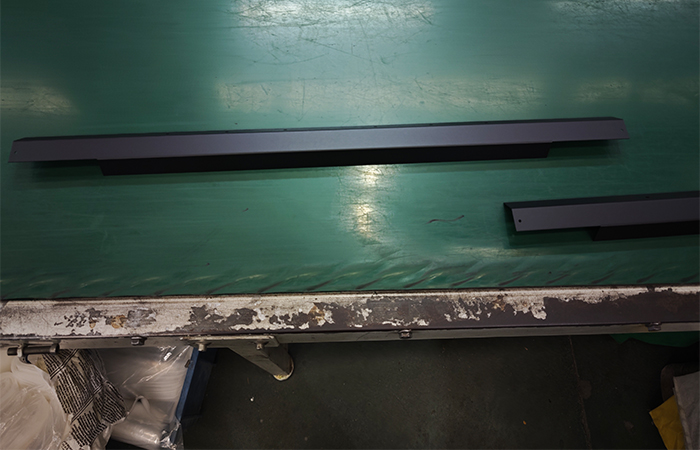

Outdoor grills face constant exposure—sunlight, rain, smoke, and handling. Behind every stable panel or shelf lies a reliable support system. Our powder coated brackets for barbecue grills provide that essential strength, while maintaining a clean, finished look.

Manufactured through precision stamping and CNC bending, each bracket is designed for performance. From folding shelves to burner trays and control panels, these parts deliver structure where it matters. The powder coating finish not only adds protection—it adds purpose.

These brackets are meant to last, even when the heat is on.

⚙️ Key Features

-

Resilient Surface Protection

Outdoor-rated powder finish resists rust, fading, and flaking, even near heat zones. -

Stable Mechanical Form

Edge-folded, ribbed, or gusseted designs improve load-bearing and reduce distortion. -

Flexible Mounting Geometry

Pre-cut holes, slotted tabs, or thread supports designed per drawing. -

Clean Aesthetic Integration

Matte black, gray, or custom color options help maintain brand consistency. -

Material Confidence

Q235 carbon steel or SUS304 stainless provides strength for dynamic loads.

📐 Technical Specifications

| Parameter | Details |

|---|---|

| Materials Supported | Carbon Steel / Stainless Steel / Aluminum Alloy |

| Thickness Range | 1.0mm – 3.0mm |

| Max Bracket Size | 500mm × 400mm |

| Surface Finish | AkzoNobel Powder Coating (Outdoor Grade) |

| Color Options | RAL/Pantone Custom, Matte Black, Graphite Gray |

| Coating Durability | Salt Spray ≥ 500h (ASTM B117) |

| Tolerance | ±0.1mm (cut), ±0.2mm (bend) |

🧩 Application Scenarios

These powder-coated brackets are widely used in:

-

Folding side tables

-

Tank shield frames

-

Hinge support arms

-

Control panel mounting flanges

-

Custom barbecue structure extensions

Whether hidden behind the grill or featured at the front—these brackets carry the load, and the brand.

🛠 Why Choose Baoxuan

-

🧷 All-in-House Fabrication – Stamping, coating, assembly done under one roof

-

🧪 Certified Coating Line – 500m powder line with AkzoNobel approval

-

🔩 Custom Assembly Holes – Made to match bolts, rivets, welding tabs

-

🧰 Prototype to Production – Fast sampling and large-batch flexibility

-

🌍 Export-Grade Quality – RoHS/REACH compliant finishes and labeling

FAQ – Powder Coated Grill Brackets

❓1. Can powder-coated brackets be used near high heat?

Yes. We use outdoor-grade polyester or epoxy-polyester powders, tested up to 200–250°C. Ideal for side frames, not direct flame contact.

❓2. Are colors customizable?

Absolutely. We support RAL and Pantone codes, and can apply matte, gloss, or textured finishes.

❓3. Do you offer brackets with pre-welded studs?

Yes. Brackets can be delivered with studs, threaded inserts, or welded tabs based on your CAD files.

❓4. Can I order small batches for pilot runs?

Yes. We support MOQ as low as 100 pcs for prototyping or initial market testing.

❓5. How durable is the powder finish?

Our coating passes ASTM B117 salt spray tests for 500–1000 hours, and is scratch/impact tested for outdoor use.

Reviews

There are no reviews yet.