Product Overview

When a machine must work without error, even the smallest component must be right.

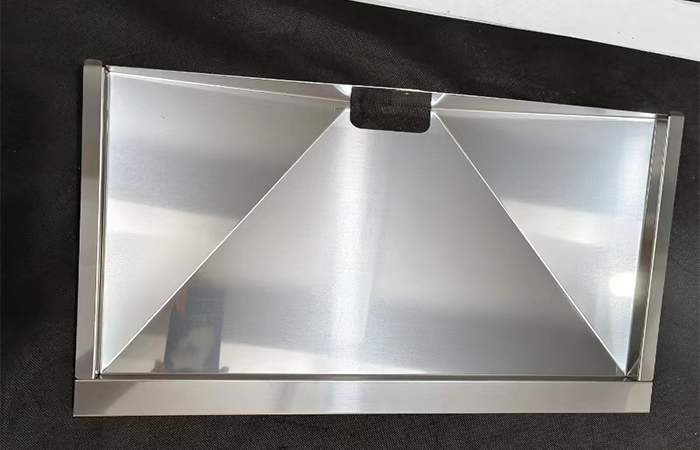

Baoxuan’s hardware stamping parts are crafted using advanced press systems and precision-engineered dies to ensure consistent quality in every unit. These are not just cut pieces of metal—they are functional, load-bearing components that integrate seamlessly into your assemblies.

We manufacture stamped hardware for a wide range of applications, including:

-

Structural support

-

Shielding and mounting

-

Enclosure assembly

The result: a part that not only fits—but performs reliably.

Key Features

-

Precision Pressing – ±0.1mm dimensional tolerance maintained across production

-

Material Variety – Carbon steel, stainless steel, brass, aluminum

-

Multi-Station Die Integration – Progressive, compound, or single-die processes available

-

Surface Options – Brushed, zinc-plated, blackened, or powder-coated finishes

-

Batch-Consistent Quality – 100% inline and final inspections

Technical Specifications

| Specification | Detail |

|---|---|

| Press Types | Open-back inclinable, high-speed (JH21 series) |

| Tonnage Range | 63T – 160T |

| Material Thickness | 0.5mm – 4mm |

| Material Options | Q235, 45#, SUS304, SUS316L, AL5052 |

| Max Stroke Rate | 85 SPM (Strokes Per Minute) |

| Die Customization | Available upon drawing confirmation |

| Secondary Operations | Bending, tapping, threading, welding, coating |

Applications of Hardware Stamping Parts

Our stamped hardware parts are widely used in:

-

Electrical and telecom equipment

-

Structural enclosures and cabinets

-

Automotive fastening and housing

-

Solar energy frames and brackets

-

HVAC system support components

Every part is engineered to withstand mechanical stress, environmental variation, and structural load—without compromise.

Why Choose Baoxuan

Complete In-House Workflow

From tooling design to stamping, surface finishing, and packaging—all done under one roof.

Tooling Optimization Support

Our engineers support die structure improvements to maximize cost-efficiency.

ISO 9001 Controlled Quality

Each production batch is tested for dimensional and functional conformity.

Global Export-Ready

Materials comply with RoHS/REACH standards and include full customs documentation.

Flexible Batches

From prototype runs to high-volume production.

Minimum Order Quantity: 100 pcs

Frequently Asked Questions (FAQ)

1. What information do I need to provide for a quotation?

Please send us 2D/3D drawings, target material, quantity, and surface finish requirements. We’ll respond within 24 hours.

2. Can you assist in designing the stamping die?

Yes. We offer die design recommendations based on geometry, material, and lifecycle. Tooling can be quoted separately or included in production cost.

3. What surface finishes are available?

Standard finishes include zinc plating, powder coating, black oxide, and brushed stainless steel.

Custom RAL or Pantone powder options are available upon request.

4. How do you ensure consistency in high-volume stamping?

We utilize progressive dies with auto-feed systems and real-time stroke monitoring. Combined with inline inspections, this ensures reliable batch performance.

5. Do you provide assembly or post-processing?

Yes. Services include threading, welding, riveting, insert installation, and sub-assembly packaging.

Reviews

There are no reviews yet.