🔧 Product Overview

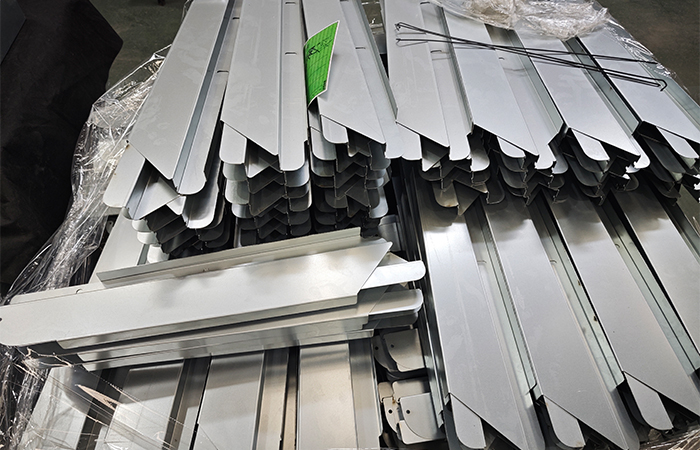

A barbecue grill’s strength often lies in the details—the brackets that silently hold everything together. Our stamping and bending brackets for barbecue grills are engineered to perform under outdoor conditions, mechanical stress, and repeated handling.

Each bracket is produced from high-strength sheet material using progressive stamping dies and multi-axis CNC bending machines. With exacting tolerances and burr-free edges, they ensure a snug fit and lasting durability in every assembly.

Whether you need corner supports, control panel mounting arms, or foldable table brackets, our solutions are built to match your grill’s structure and lifespan.

⚙️ Key Features

-

Precision Formed

±0.1mm stamping and ±0.2mm bending tolerances ensure smooth assembly and alignment. -

Material Versatility

Q235 carbon steel, SUS304 stainless, or AL5052 aluminum—selected per your requirements. -

Surface Finishing Options

Outdoor powder coating, zinc plating, or brushed finish for visual appeal and corrosion resistance. -

Custom Mounting Features

Pre-punched holes, threaded inserts, or tabs based on your CAD drawings. -

Structural Performance

Supports static and dynamic load without deformation or loosening.

📐 Technical Specifications

| Parameter | Details |

|---|---|

| Material Types | Carbon Steel / Stainless Steel / Aluminum Alloy |

| Thickness Range | 1.0mm – 4.0mm |

| Forming Methods | Progressive Stamping + CNC Bending |

| Surface Finish | Black Powder Coating / Galvanized / Brushed |

| Hole Size Tolerance | ±0.1mm |

| Edge Processing | Laser deburred, rounded corners |

| Max Size | 600mm × 400mm (customizable) |

🧩 Application Scenarios

These brackets are widely used in:

-

Control panel mounting

-

Grill leg joint reinforcement

-

Side table folding supports

-

Door hinge carriers

-

Burner tray or valve holders

In every case, these components are designed not just to fit—but to function perfectly in the background, season after season.

🛠 Why Choose Baoxuan

-

🧷 Integrated Manufacturing – From stamping die design to powder coating, all processes in-house

-

🔍 Tight Quality Control – Measurements taken at each process checkpoint

-

🧪 Stress Tested – Brackets are tested for bending fatigue and salt spray before shipment

-

🧰 Flexible Batch Sizes – From sample prototypes to high-volume orders

-

🌍 Ready for Export – RoHS / REACH materials with all customs documentation provided

FAQ – Barbecue Grill Bracket Processing

❓1. What are your capabilities for custom stamping brackets?

We design and fabricate progressive or compound dies and can produce multi-step bracket shapes with mounting holes, bends, and tabs—all in one process.

❓2. Which material is better for outdoor grill brackets?

Carbon steel with powder coating is durable and cost-effective. For coastal or high-humidity regions, SUS304 stainless steel is ideal due to its corrosion resistance.

❓3. Do you offer threaded holes or weld nuts?

Yes. We support press-fit nuts, weld nuts, and tapped holes during or after stamping. Please indicate in your drawing.

❓4. Can you assist in optimizing my bracket design?

Absolutely. Our engineering team provides DFM suggestions to improve strength, reduce cost, and speed up production.

❓5. What is your typical lead time?

-

Samples: 5–7 working days

-

Mass Production: 10–15 working days, depending on quantity and finish

Reviews

There are no reviews yet.